RETHINKING THE ROLE OF SUPPLIER TECHNICAL SUPPORT

Challenge

The Field Engineering team provides hundreds of line reviews, product tear downs, and other technical support services every year to identify cost savings for our customers. The challenge is getting the cost savings implemented because fastener/ fastening issues are generally a low priority.

Solution

The Engineering Integration Program at Field was designed to provide our key customers with the in house fastener support and knowledge they need when dealing with fastening issues. Key components of this unique approach:

- Field has the top fastener engineers in the industry working with our key customers, at their sites providing engineering support

- Traditional roles are changed to allow Field Engineers to move beyond submitting recommendations to getting them implemented

- With appropriate direction and controls, Field manages the process through an Engineering Change Request

- Field engineers focus on fastening while our customer’s engineers can focus on the product

Results

- More recommendations become REAL savings

- The customers engineers spend more time using their core competencies

- Improved fastening quality at a lower cost by utilizing Field’s core competencies

- Shorter new product development time

- Fewer design changes after production begins

- Less proliferation of fastener SKU’s

Example

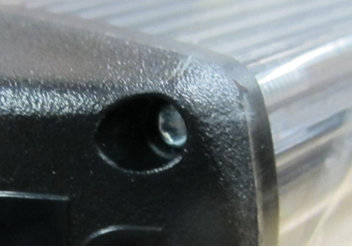

An onsite Field engineer became aware of a “made to print” special fastener that was not working properly. Here’s what Field did:

- The Field engineer inspected the fastener and identified thread quality issues

- Field identified several alternate standard fasteners and secured samples for testing

- Field tested the options, provided test data on the current and proposed fastener, and recommended a standard, lower cost part with greater availability

- The change was approved and the Field Engineer processed the ECR

The Field Engineering Integration Programs’ main goal is to help our customers implement more cost savings. Our Onsite Field Engineers look for cost savings at every opportunity, and this case is a great example of our engineers fixing a problem that may not have received as much attention by the customer’s engineering team.

This approach is unique and required rethinking the supplier’s role when providing technical support.

Field's Engineering Initiative

- Increase the suggestions that become savings

- Reduce the customers efforts and increase Field role in fastener engineering activities

- Allows the customer to focus on their core competencies

- Creates a new relationship with Field and our customers