- Fastening Solutions

- Industries

- Why Field

- About

- Resources

- 815-637-9002

- Fastening Solutions

- Industries

- Why Field

- About

- Resources

- 815-637-9002

- Careers

- Suppliers

- Contact Us

- IFI Connection

- Search

Vendor-managed inventory (VMI) programs are about reduction. VMI helps you reduce:

VMI is also about increasing turns, availability, and efficiency.

Here’s how Field Fastener does VMI: through real-time communication between your inventory and our global supply base, we act as an extension of your team, ensuring you have the right parts at the right time — and at the most competitive price on the market.

Vendor-managed inventory (VMI) is a practice in which a supplier takes full responsibility for managing a buyer’s inventory at that buyer’s location. With the right tools, it is easier for a supplier to effectively manage inventory than for buyers to try and manage hundreds or thousands of part numbers on their own. Lean on the Field Team. Implementing a customized VMI system means Field can ensure the right product is always available.

Lowering inventory levels can amount to significant savings. The best VMI systems use data to monitor usage and ensure proper inventory levels, maximize availability, and minimize costs.

Procurement personnel spend less time managing the class ‘C’ commodities so they can spend more time on class ‘A’ or ‘B’ items and commodities that have a greater overall impact.

Since vendor-managed inventory (VMI) systems are actively managed, the supplier can spend time collaborating with the buyer on cost reduction projects and other proactive initiatives. This open communication between suppliers and buyers leads to long-lasting, positive relationships that are focused on quality.

If none of these approaches to VMI meets your objectives, we will develop an approach that does. The best VMI suppliers do not believe in a uniform system for each customer. Processes are different across different industries, and what works for a customer at one plant may not be the right fit at another location. The best systems are the ones that are tailored to meet the customer’s needs. When designing a new VMI system, we consider the number of parts in the system, inventory, quality requirements, material handling, and storage, ensuring that our customers have a system in place that is right for them.

An in-plant store system is ideal when part volume warrants replenishment several times per week. For customers who want an active, daily, on-site, supplier inventory management system and on-site vendor warehousing, we maintain inventory and staff within your manufacturing site. In many cases, your Field rep will also serve as your account manager, managing the inventory in the supply chain as well.

Using a barcode scanner, a Field rep visually audits stock quantities and creates a personalized order for items below the minimum quantity. Your Field technician will make inventory decisions on-site and utilize technology to ensure product availability, focusing on continuous improvement of the system.

With this method, the supplier holds inventory at your location and retains ownership of the inventory until it’s moved out of consignment, which triggers payment. This is useful for situations in which the desired inventory turns cannot be realized using other methods.

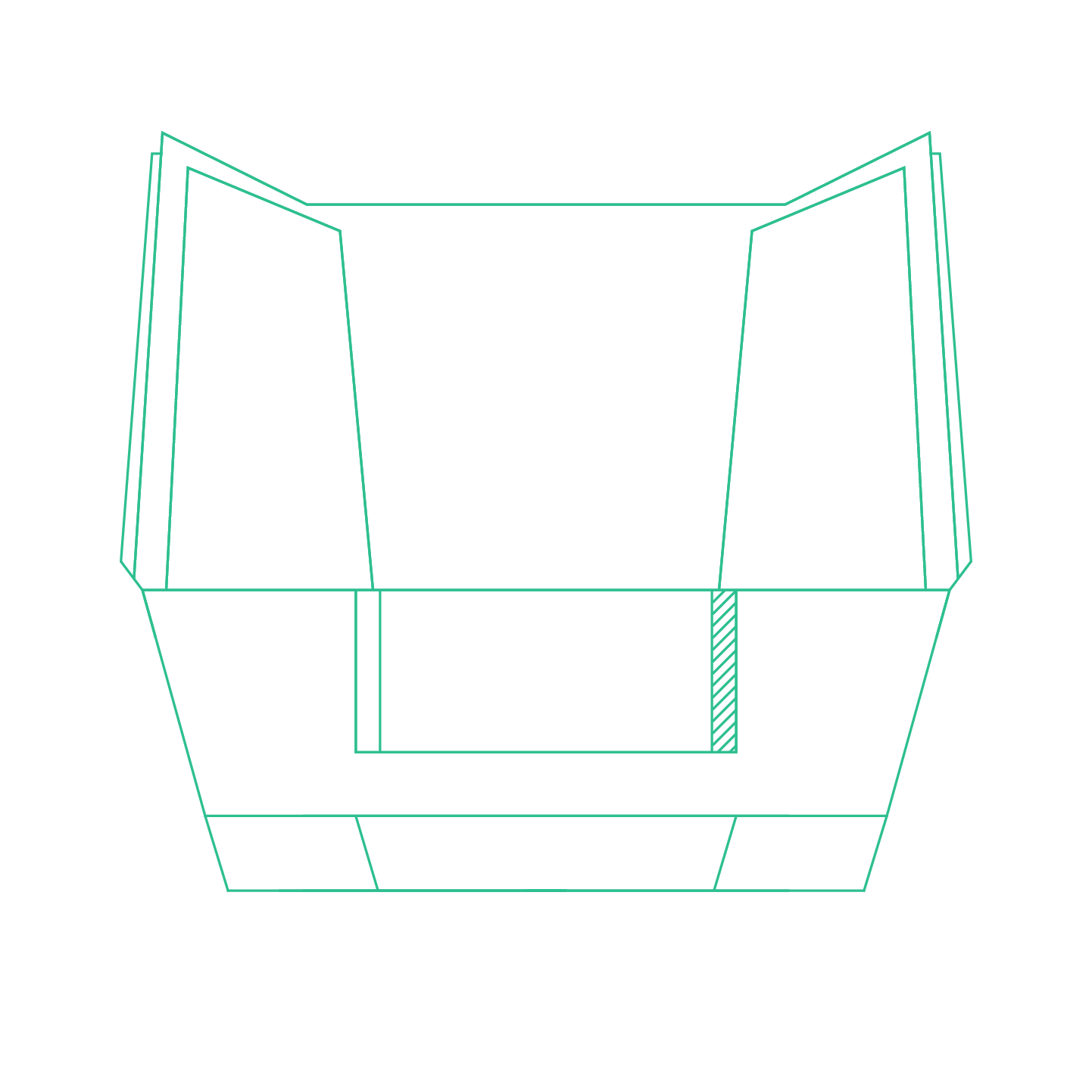

This system is for manufacturers who prefer to maintain inventory as close to the point at which it’s used as possible. This promotes greater efficiency, as inventory is readily at an assembly station when it’s needed. It is important to properly size the bins to minimize the cost of replenishing bins too frequently.

The best vendor-managed inventory solutions are ones that:

Is VMI the right fit for the parts you’re currently sourcing and stocking? Here’s how to tell.

VMI or vendor managed inventory allows our team at Field to maintain your correct and required inventory levels at your location. This eliminates your need to manage inventory, reduces labor and costs, and increases turns, availability, and efficiency. This is done through a variety of systems that are customized to your requirements. Implementing a customized VMI system means Field can ensure the right product is always available at the right price.

Field manages the fasteners and class C commodities for any business. This is an excellent program for high or medium volume parts, parts that are often out of stock when needed, and parts that do not require inspection before stocking.

Our VMI service ensures that your inventory is maintained at the required levels. This reduces the cost of having too much inventory and also reduces the risk of not having the fasteners you need. Your team does not have to spend time or money on the process; we manage everything for your business.

We customize vendor managed inventory programs to meet the specific demands of our customers. Field has data driven tools in place to analyze consumption patterns and adjust inventory levels as needed.

Yes, our VMI programs are designed to be used onsite at your location or across multiple locations. Your Field Rep will make inventory decisions on-site and utilize technology to ensure product availability focusing on continuous improvement of the system.

Field’s data-driven approach to VMI dramatically reduces costs, inventory, and overhead for your business while increasing turns and availability and improving manufacturing process efficiencies.

Our global reach means we can provide product and vendor-managed inventory services anywhere you need them in the world. We’ll efficiently and cost-effectively manage your requirements while customizing a program to fit your specific needs.

The proactive, engineering-based management of our vendor-managed inventory program means you’ll always have appropriate stocking levels – including vendor-managed inventory fasteners – based on your business conditions and needs. Data-driven above all else, we’ll perform a root cause analysis on any shortage that occurs and provide you with data that can help your organization accurately forecast.

Moreover, our proactive continuous improvement process means we always look to improve the program before failures occur, reducing your downtime.