- Fastening Solutions

- Industries

- Why Field

- About

- Resources

- 815-637-9002

- Fastening Solutions

- Industries

- Why Field

- About

- Resources

- 815-637-9002

- Careers

- Suppliers

- Contact Us

- IFI Connection

- Search

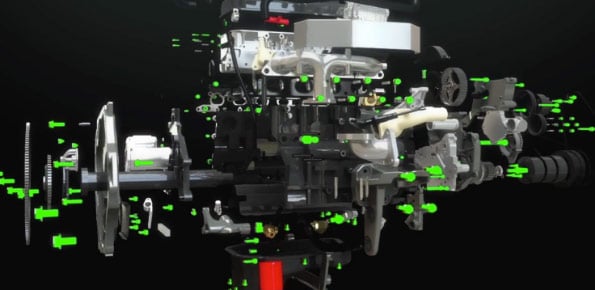

At Field, we are your on-demand, data-driven, full-service fastener hardware distributor and engineering partner that provides yearly cost savings to our customer through an efficient and accurate evaluation of total assembly cost. With the application of an effective vendor-managed inventory approach, we help ensure the availability of product, elimination of waste, and a reduction in your costs for inventory, labor, and overhead.

Field is more than components or even an industrial fastener supplier. We are your dedicated partner. With a proactive, data-driven approach to vendor-managed inventory services and programs, we deliver cost savings and efficiency across the board to ensure the availability and accessibility of the faster hardware and other products you need at an optimized cost, without sacrificing the product quality required.

Because we work with more than 900 global suppliers, we have access to all of the “C” class fastener or commodity you need for your applications or projects. Simply put, if your business uses the fastener, we can source it at exceptional quality and at a competitive price per part. We are your fastener cost saving experts.

-1.png?width=595&height=290&name=Untitled%20design%20(1)-1.png)

At Field, we promote a business culture that highly values people, including our customers, team members, suppliers, and our surrounding community. We are not only goal-oriented and results-driven, we are also family focused. We want our customers, business partners, and all who interact with us to love working with us.

We serve industries worldwide working with our base of 900 suppliers to ensure you get the best quality parts at the most reasonable prices.

Looking for fastener companies near you? Look no further than Field for the industrial fastener engineering solutions you need.

Engineering review and part redesign

During a technical line review at a prospective customer’s manufacturing facility, the Field engineering team observed inefficiencies with an assembly process.

Offered customer $65,000 and 242 labor hours in savings

During a technical line review of a customer’s facility, the Field team observed the components and methods of manufacturing used to assemble a railcar.

Being Integrated allows Field to not only identify cost savings opportunities, but also plan and implement them

During a technical line review, a Field engineering team member noted a signal light being produced used a separate right and left side end cap.