- Fastening Solutions

- Industries

- Why Field

- About

- Resources

- 815-637-9002

- Fastening Solutions

- Industries

- Why Field

- About

- Resources

- 815-637-9002

- Careers

- Suppliers

- Contact Us

- IFI Connection

- Search

As your on-demand engineering department, Field is the best in the industry at producing immediate and ongoing cost savings through our value added engineering-based approach to fastening. From line reviews that yield efficiency and ergonomics recommendations to product teardown and fastener part consolidation, the experts at Field can give your organization a competitive edge by improving product designs, quality, and safety and identifying cost savings.

When you need reliable fastener engineering solutions, Field has you covered.

Reduce the number of different fasteners in use. On a global level, we can create a database to identify consolidation candidates. Alternatively, we can focus on a specific product line, assembly area, or group of fasteners. In addition to the part characteristics, each application is reviewed for consolidation potential.

We recommend changes to improve the accuracy and clarity of the specifications by using our innovative technical approach to fastening solutions and by considering standard parts to lower costs.

Field representatives observe every step in the assembly process to identify improvements in fastening techniques and methods. A report is submitted identifying current methods and recommendations for improvements, including cost analysis and performance comparisons of alternate fastening methods. Product validation is completed by Field’s engineering team to reduce the time spent by the customer – a key part of our engineering value added services.

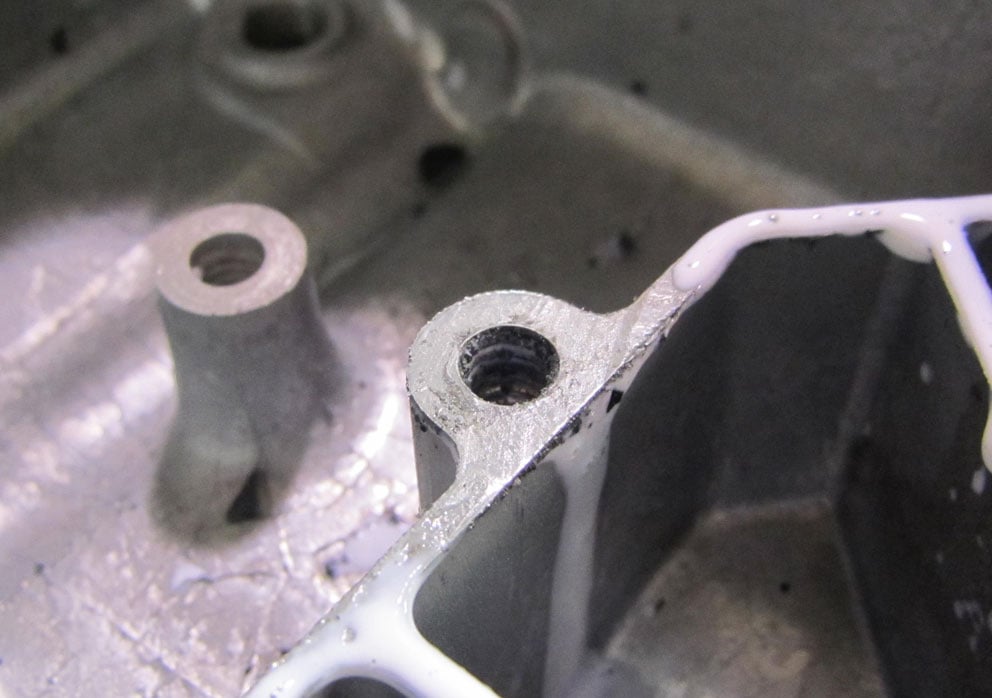

Most effective when done in conjunction with an assembly line review, the product is disassembled with each application reviewed. Recommendations for cost reduction for manufacturing and assembly, and quality improvement are identified and documented.

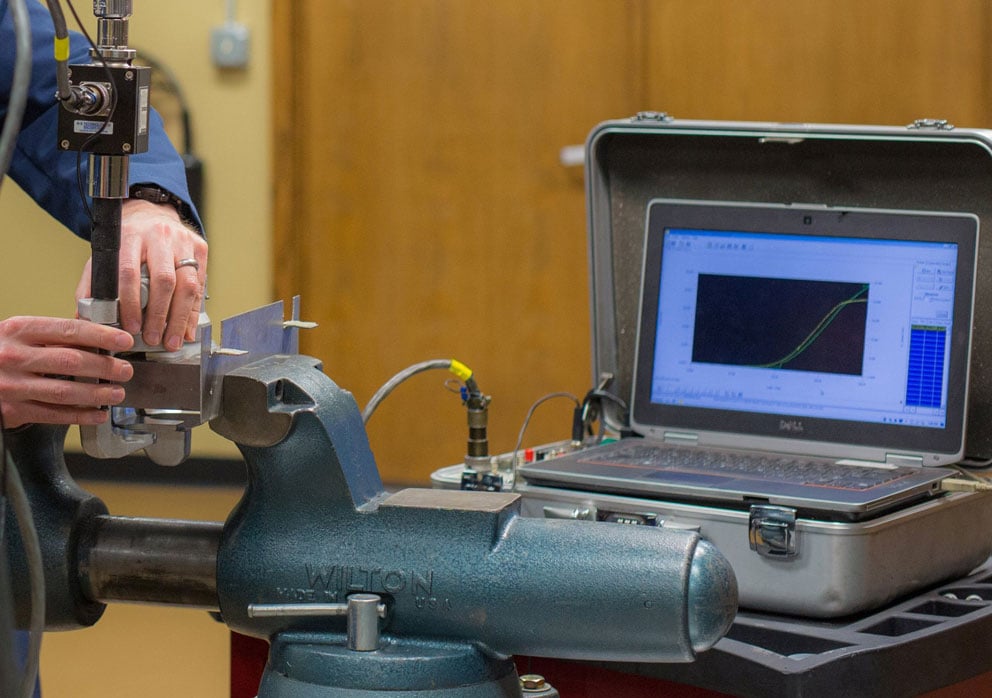

An analysis of failed samples to identify the probable cause of failure. Methods include evaluation of dimensional and metallurgical characteristics, evaluation of the fracture surface, and other attribute and performance testing. Findings are submitted in a technical report.

This is the best time to evaluate fasteners for lowering cost and improving product quality. The Field team places emphasis on determining optimum fastening methods as part of our fastener and fastening engineering solutions. Bringing the Field team in at the beginning means we can provide cost savings and ensure quality right from the start.

Our most frequently requested service, we identify specific problem areas for the Field team to evaluate, conduct performance testing on, and develop detailed recommendations. The team then reviews their report with Engineering.

Our experience in the feeding, orienting, and installation of fasteners allows us to be a valuable resource in this area. Value added engineering services include making recommendations for the design of the mating parts and torque control methods.

Through our Field University program, Field regularly trains everyone from assembly line workers to engineers on our smarter industrial fastener engineering solutions and processes. Depending on the audience, training is tailored to meet specific needs and objectives and is always designed to help you improve workflow efficiencies, reduce costs, and improve quality. Learn more about our training programs.

-1.png?width=1768&height=986&name=Field%20University%20(Edited)-1.png)

Value-added engineering at Field allows our team of fastening experts to design the ideal line of fasteners for your specific applications. Value added engineering also means that we will help you through any and all issues you are facing when it comes to fasteners. Using this engineering service allows you to save money and time by having fasteners that are easy to install, provide the features you need, and increase productivity and safety.

We work closely with our customers to determine the best approach to reaching the specific changes they wish to accomplish. This can include fastener consolidation, print reviews, assembly line analysis, product teardown for quality improvement, failure analysis, and new design review. We also offer application problem solving and technique consultation for any business.

The key factor in value-added engineering is to identify areas of inefficiency, quality control, or bottlenecks in productivity and to develop a plan to address these issues. This is an in-depth process that helps to streamline the use of fasteners throughout the business, resulting in lower operating costs and higher efficiency.

At Field, our value-added engineering team can work with your team to create more effective industrial fastener solutions and processes. Companies can use our services when inefficiencies are noticed, when quality control drops, during new product design, or when the cost of operations increases.

We also offer Field University, which allows our team to train your staff to continue to find ways to create improvements in production and processes related to industrial fasteners.